Precision Perfected: Factory vs. Field Calibration

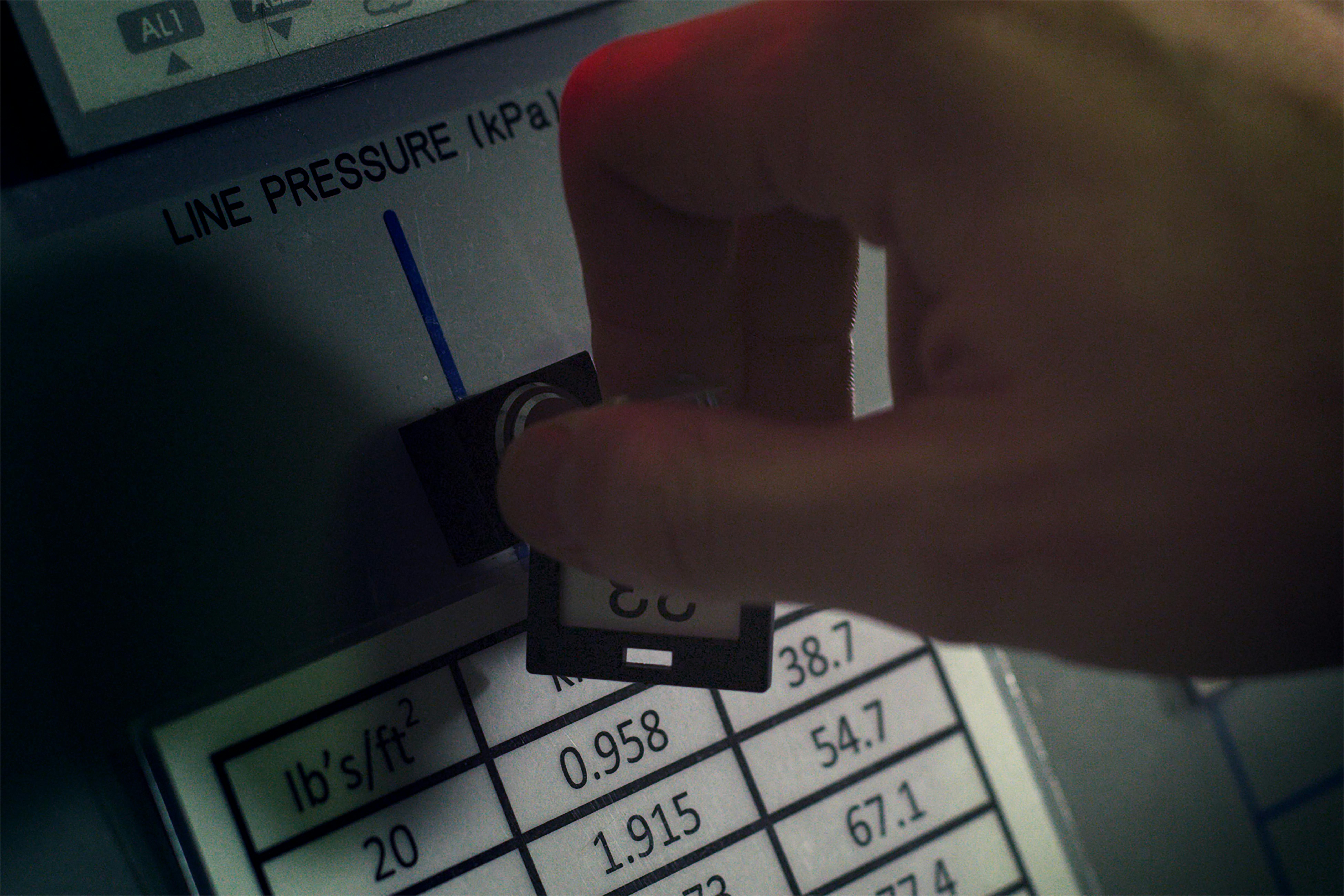

Calibration accuracy directly impacts the reliability of your measurement instruments, making the choice between factory and in-field calibration crucial for operational

Calibration accuracy directly impacts the reliability of your measurement instruments, making the choice between factory and in-field calibration crucial for operational

Accurate sensor data drives better decisions across industries, yet budget-friendly sensors often require careful calibration workflows to deliver reliable results consistently.

In today’s fast-paced development environment, managing calibration parameters effectively can make the difference between system success and failure. Whether you’re working

Data accuracy depends on more than just precise instruments—it requires clean data before any calibration adjustments take place, ensuring reliable results

Edge computing is transforming how devices process data, but maintaining accuracy in real-time environments remains a critical challenge that demands innovative

Precision calibration in remote environments demands strategic planning, robust systems, and adaptable methodologies that ensure measurement accuracy despite challenging conditions and

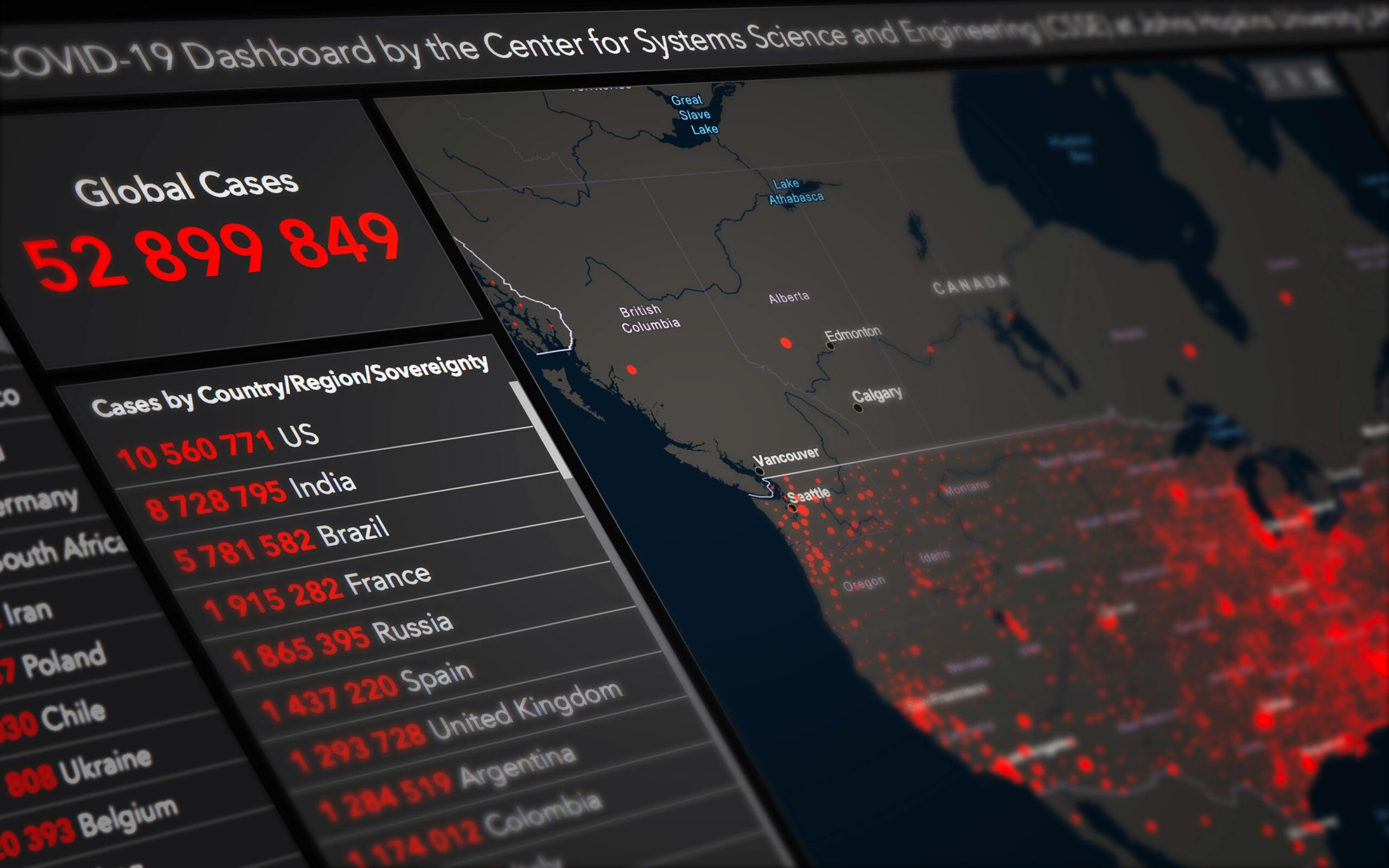

Visual dashboards revolutionize calibration tracking by transforming complex data into actionable insights, helping organizations maintain compliance, reduce downtime, and optimize equipment

Outliers can silently sabotage your calibration results, turning precise measurements into unreliable data. Understanding how to identify and handle these anomalies

In today’s data-driven landscape, understanding the reliability of predictions is just as crucial as the predictions themselves, transforming how organizations make

Precision in workflows transforms case studies from theoretical exercises into actionable insights that drive measurable business outcomes and competitive advantages. In