Microbial biosensors are transforming how we monitor cleanliness in indoor environments, offering real-time detection of pathogens and contaminants with unprecedented accuracy and speed.

🔬 The Dawn of Intelligent Contamination Detection

Traditional methods of detecting microbial contamination have relied on time-consuming laboratory analyses that can take days to yield results. In hospitals, food processing facilities, pharmaceutical manufacturing plants, and public spaces, this delay can mean the difference between preventing an outbreak and managing a full-scale health crisis. The emergence of microbial biosensors represents a paradigm shift in how we approach environmental monitoring and hygiene management.

These sophisticated devices combine biological recognition elements with physical transducers to detect specific microorganisms or their metabolic products. Unlike conventional sampling methods that require trained technicians to collect samples and transport them to laboratories, biosensors provide immediate feedback, enabling rapid decision-making and intervention. This technological advancement is not merely an incremental improvement—it’s a fundamental reimagining of cleanliness assessment.

Understanding the Science Behind Microbial Biosensors

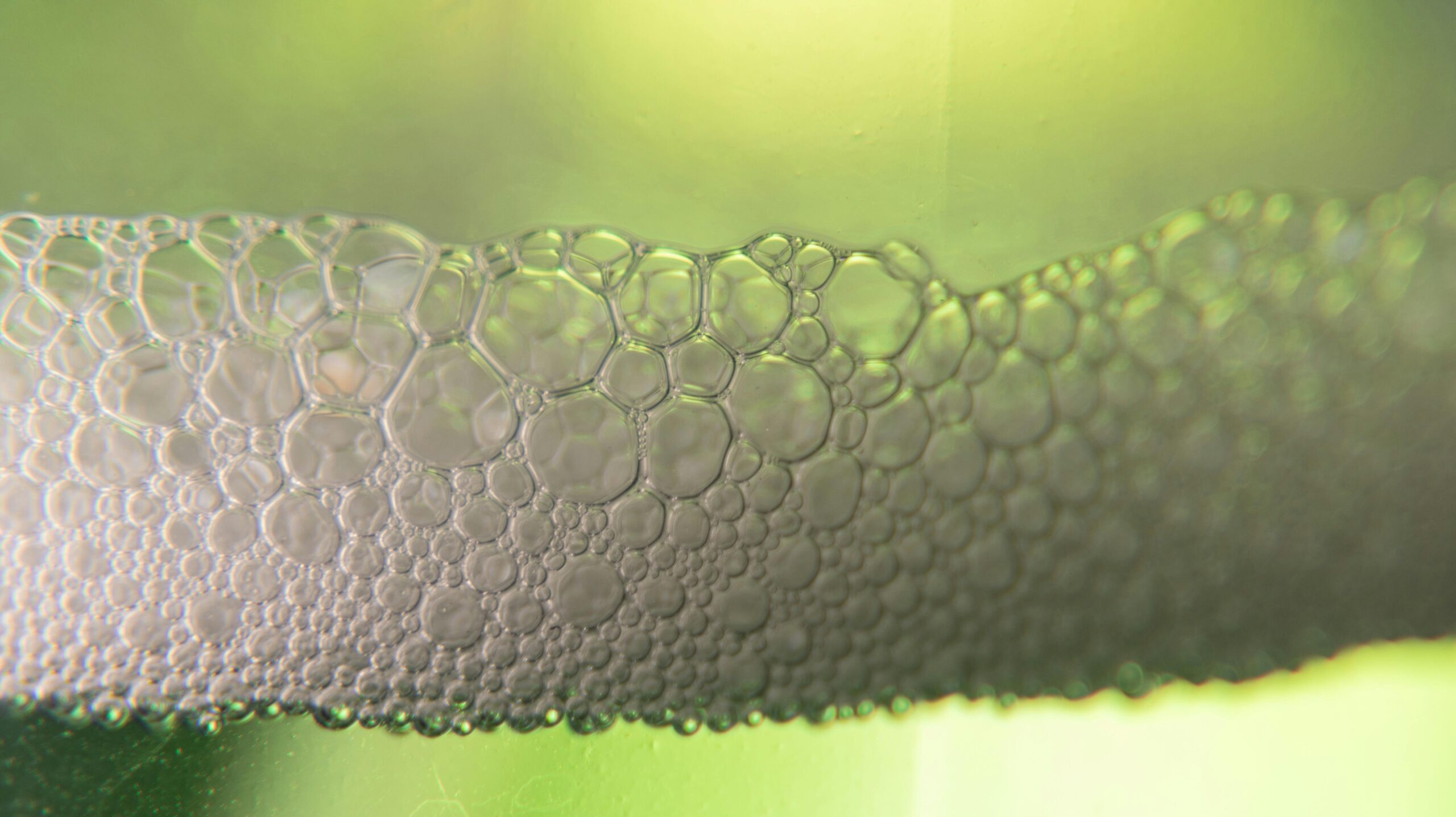

At their core, microbial biosensors function through a beautifully elegant biological-electronic interface. The biological component, known as the bioreceptor, interacts specifically with target microorganisms. This interaction triggers a measurable signal that the transducer converts into an electrical output, which is then processed and displayed as readable data.

The bioreceptor might consist of antibodies, enzymes, nucleic acids, or even whole cells designed to recognize specific pathogens like E. coli, Salmonella, Staphylococcus aureus, or airborne viruses. When the target microorganism binds to the bioreceptor, it causes a change in the system—perhaps an electrical current alteration, a shift in optical properties, or a mass change—that the transducer detects and quantifies.

Types of Transduction Mechanisms 📊

Different biosensor designs employ various transduction methods, each with distinct advantages:

- Electrochemical biosensors measure changes in electrical properties such as current, potential, or conductance when microorganisms interact with the electrode surface

- Optical biosensors detect changes in light absorption, fluorescence, or refractive index caused by microbial binding

- Piezoelectric biosensors measure mass changes on a crystal surface when microorganisms attach to the bioreceptor

- Thermal biosensors detect heat changes produced by enzymatic reactions involving target microorganisms

- Magnetic biosensors utilize magnetic nanoparticles conjugated with bioreceptors to detect pathogen binding

Transforming Air Quality Monitoring

Air sampling for microbial contamination has traditionally been a cumbersome process involving impactors, filters, or liquid impingers that capture airborne particles for subsequent laboratory analysis. Microbial biosensors are revolutionizing this field by enabling continuous, real-time monitoring of air quality in critical environments.

In healthcare settings, surgical suites require stringent control of airborne pathogens. Traditional monitoring might reveal contamination only after procedures have been performed, potentially exposing patients to infection risks. Biosensor-equipped air sampling systems can provide continuous surveillance, triggering immediate alerts when microbial counts exceed safe thresholds or when specific pathogens are detected.

The aerospace industry has begun incorporating biosensor technology into air filtration systems for spacecraft and aircraft, where closed environments make air quality monitoring absolutely critical. Similarly, clean rooms in semiconductor manufacturing and pharmaceutical production benefit enormously from real-time microbial detection, as contamination can ruin entire production batches worth millions of dollars.

Detecting Airborne Pathogens in Real-Time ⚡

Modern air sampling biosensors can detect remarkably low concentrations of airborne bacteria, fungi, and viruses. Some advanced systems achieve detection limits below 10 colony-forming units per cubic meter of air, with response times measured in minutes rather than days. This capability proved particularly valuable during the COVID-19 pandemic, as researchers developed biosensors specifically designed to detect SARS-CoV-2 viral particles in indoor air.

These devices typically draw air through a sampling chamber where airborne microorganisms are captured on biosensor surfaces functionalized with specific antibodies or nucleic acid probes. The captured pathogens then trigger the detection mechanism, generating quantifiable signals that indicate both the presence and approximate concentration of target organisms.

Surface Sampling Applications Across Industries

Surface contamination monitoring represents perhaps the most immediately practical application of microbial biosensor technology. Every industry that maintains hygiene standards—from healthcare to food service, from public transportation to childcare facilities—can benefit from rapid, accurate surface testing.

Traditional surface sampling involves swabbing surfaces, transferring samples to culture media, and waiting 24-48 hours for bacterial colonies to grow. During this waiting period, contaminated surfaces may continue spreading pathogens to workers, customers, or patients. Biosensor-based surface sampling delivers results in 15 minutes to two hours, enabling immediate corrective action.

Healthcare and Hospital Hygiene 🏥

Healthcare-associated infections affect millions of patients worldwide annually, with contaminated surfaces serving as significant transmission vectors. Microbial biosensors allow hospital staff to verify cleaning effectiveness immediately after disinfection procedures, ensuring that high-touch surfaces like bed rails, door handles, and medical equipment are genuinely pathogen-free before the next patient encounter.

Some hospitals have implemented continuous monitoring systems where biosensor arrays are permanently installed on frequently touched surfaces, providing constant surveillance for concerning pathogens like methicillin-resistant Staphylococcus aureus (MRSA) or Clostridioides difficile. These systems generate alerts when contamination is detected, triggering immediate cleaning protocols.

Food Safety and Processing Facilities

The food industry loses billions annually to contamination events that result in product recalls, facility closures, and illness outbreaks. Microbial biosensors offer food processors a powerful tool for preventing contamination rather than merely detecting it after the fact.

Surface sampling in food processing environments can identify Listeria, Salmonella, E. coli, and other foodborne pathogens on preparation surfaces, cutting equipment, and packaging machinery. The rapid turnaround time means that contamination can be addressed before it enters the food supply chain, protecting both consumers and brand reputation.

Advantages Over Traditional Detection Methods

The superiority of microbial biosensors over conventional detection methods extends across multiple dimensions that matter in practical applications:

| Feature | Traditional Methods | Microbial Biosensors |

|---|---|---|

| Detection Time | 24-72 hours | 15 minutes – 2 hours |

| Sample Processing | Laboratory required | On-site testing |

| Technical Expertise | Trained microbiologists | Minimal training needed |

| Quantification | Manual colony counting | Automated digital readout |

| Cost per Test | $50-200 | $10-50 |

| Continuous Monitoring | Not practical | Fully supported |

Beyond these measurable advantages, biosensors offer operational benefits that transform hygiene management workflows. The immediate feedback enables adaptive cleaning protocols where resources are deployed exactly where and when contamination is detected, rather than following rigid schedules that may waste effort on already-clean surfaces while missing problematic areas.

Emerging Technologies and Future Developments 🚀

The field of microbial biosensors continues evolving at a remarkable pace, with several cutting-edge developments promising even greater capabilities in the near future.

Smartphone-Integrated Detection Systems

Researchers have developed biosensor systems that connect directly to smartphones, using the device’s camera and processing power to analyze results. These portable systems democratize access to sophisticated microbial testing, potentially enabling routine hygiene monitoring in resource-limited settings. Users simply collect a sample, insert it into the smartphone-connected biosensor module, and receive results on their device within minutes.

Multi-Pathogen Detection Arrays

While early biosensors typically detected single target organisms, newer array-based systems can simultaneously test for dozens of different pathogens in a single sample. These multiplexed biosensors provide comprehensive contamination profiles rather than simple yes/no answers for individual organisms, offering a more complete picture of hygiene status.

Artificial Intelligence Integration

Machine learning algorithms are being incorporated into biosensor systems to improve accuracy, reduce false positives, and predict contamination patterns. AI-enhanced biosensors can learn the microbial baseline for specific environments and alert operators to unusual deviations that might indicate hygiene protocol failures or emerging contamination sources.

Implementation Challenges and Practical Considerations

Despite their tremendous promise, microbial biosensors face several challenges that organizations must consider when implementing these technologies. Understanding these limitations ensures realistic expectations and successful deployment.

Biosensor stability and shelf life remain ongoing concerns. The biological components can degrade over time, particularly when exposed to temperature fluctuations or humidity changes. Most biosensors require refrigerated storage and have limited operational lifespans, necessitating regular replacement and careful inventory management.

Specificity and cross-reactivity issues occasionally arise when non-target organisms trigger biosensor responses, generating false positive results. While modern biosensors demonstrate excellent specificity, closely related microorganisms or high concentrations of background flora can sometimes interfere with detection.

Cost-Benefit Analysis for Organizations 💰

Organizations considering biosensor implementation must weigh initial investment costs against long-term savings and risk reduction. A comprehensive biosensor program might require substantial upfront expenditure for equipment, training, and integration with existing quality management systems.

However, the return on investment often becomes apparent quickly. Preventing a single foodborne illness outbreak or healthcare-associated infection event can save far more than the entire biosensor system costs. Additionally, the efficiency gains from eliminating laboratory delays and optimizing cleaning protocols typically generate ongoing operational savings.

Regulatory Landscape and Quality Standards

As microbial biosensors transition from research laboratories to commercial applications, regulatory frameworks are evolving to ensure these devices meet appropriate performance and reliability standards. Various international organizations have developed guidelines for validating biosensor performance in specific applications.

In healthcare settings, biosensors intended for diagnostic purposes must typically undergo rigorous approval processes through agencies like the FDA or European Medicines Agency. Environmental monitoring biosensors face less stringent requirements but still must demonstrate adequate sensitivity, specificity, and reproducibility for their intended applications.

Food safety applications often require biosensors to meet standards established by organizations like the Association of Official Agricultural Chemists (AOAC), which provides validation protocols ensuring that alternative methods perform comparably to traditional reference methods.

Training and Workforce Adaptation 👥

Successfully integrating microbial biosensors into existing hygiene management programs requires thoughtful workforce training and adaptation. While these devices are designed for ease of use, operators must understand proper sampling techniques, result interpretation, and appropriate responses to detection events.

Organizations typically find that transitioning to biosensor-based monitoring creates new roles while transforming existing ones. Environmental services staff gain new responsibilities for routine biosensor testing, while quality assurance personnel shift from coordinating laboratory sample logistics to analyzing real-time data streams and identifying contamination trends.

The immediacy of biosensor results also demands changes to response protocols. Organizations must establish clear escalation procedures that define exactly what actions should be taken when contamination is detected, who is responsible for implementation, and how effectiveness will be verified.

The Path Forward: Integrating Biosensors Into Comprehensive Hygiene Strategies

Microbial biosensors represent powerful tools, but they deliver maximum value when integrated into comprehensive, thoughtfully designed hygiene management strategies rather than deployed as standalone solutions. The most successful implementations combine biosensor technology with traditional good practices, environmental design improvements, and continuous quality improvement methodologies.

Forward-thinking organizations are creating layered hygiene systems where biosensors provide the real-time monitoring backbone, supplemented by periodic traditional laboratory testing that validates biosensor performance and detects organisms outside the biosensor target range. This hybrid approach balances speed with comprehensiveness, ensuring no critical contamination goes undetected.

The data generated by continuous biosensor monitoring also enables sophisticated analytics that were previously impossible. Organizations can identify temporal patterns in contamination, correlate hygiene failures with specific environmental conditions or process changes, and continually refine their cleaning protocols based on objective evidence rather than assumptions.

Transforming Our Relationship With Cleanliness ✨

Perhaps the most profound impact of microbial biosensors extends beyond technical specifications and operational metrics to fundamentally transform how we conceptualize and relate to cleanliness itself. Traditional hygiene management operated largely on faith—faith that established protocols were being followed correctly, faith that visible cleanliness indicated microbial safety, faith that periodic testing provided adequate assurance.

Biosensors replace faith with knowledge, transforming hygiene from an assumed state into a verified condition. This shift empowers everyone from hospital patients to restaurant diners to airplane passengers with confidence that the spaces they occupy have been objectively confirmed as safe.

As these technologies become more affordable and widespread, we may witness cleanliness verification becoming as routine and expected as temperature checks or security screening. The invisible microbial world, once accessible only through specialized laboratory analysis, becomes immediately knowable, driving standards and expectations ever higher.

The revolution in cleanliness enabled by microbial biosensors represents more than technological advancement—it embodies a fundamental enhancement of human capability to create and maintain healthy environments. As we continue refining these remarkable devices and expanding their applications, we move closer to a future where preventable infections and contamination events become increasingly rare, protected by the vigilant, invisible guardians of our microbial biosensors.

Toni Santos is an environmental sensor designer and air quality researcher specializing in the development of open-source monitoring systems, biosensor integration techniques, and the calibration workflows that ensure accurate environmental data. Through an interdisciplinary and hardware-focused lens, Toni investigates how communities can build reliable tools for measuring air pollution, biological contaminants, and environmental hazards — across urban spaces, indoor environments, and ecological monitoring sites. His work is grounded in a fascination with sensors not only as devices, but as carriers of environmental truth. From low-cost particulate monitors to VOC biosensors and multi-point calibration, Toni uncovers the technical and practical methods through which makers can validate their measurements against reference standards and regulatory benchmarks. With a background in embedded systems and environmental instrumentation, Toni blends circuit design with data validation protocols to reveal how sensors can be tuned to detect pollution, quantify exposure, and empower citizen science. As the creative mind behind Sylmarox, Toni curates illustrated build guides, open calibration datasets, and sensor comparison studies that democratize the technical foundations between hardware, firmware, and environmental accuracy. His work is a tribute to: The accessible measurement of Air Quality Module Design and Deployment The embedded systems of Biosensor Integration and Signal Processing The rigorous validation of Data Calibration and Correction The maker-driven innovation of DIY Environmental Sensor Communities Whether you're a hardware builder, environmental advocate, or curious explorer of open-source air quality tools, Toni invites you to discover the technical foundations of sensor networks — one module, one calibration curve, one measurement at a time.